OPTICAL INSTRUMENTATION FOR THE MONITORING OF INDUSTRIAL RESIDUES

OPTICAL INSTRUMENTATION FOR THE MONITORING OF INDUSTRIAL RESIDUES

The remote monitoring technique CMAX-DOAS (Concurrent Multi-Axis Differential Optical Absorption Spectroscopy) automatically identifies and quantifies the concentration of residual industrial gases emitted into the environment during industrial processes, such as: SO2, NO2, NO3, CS2, HNO2, CH2O, ClO2 y OCH2, among other atmospheric gases. The measurements permit vertical profile reconstruction and the temporal series of the gases, with a results sample in real time, without the need for technical assistance or radiometric calibration, of great interest to refineries, iron and steel plants, mines, thermoelectrical plants and other industries.

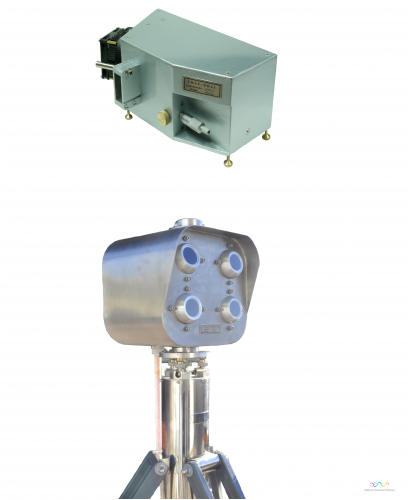

HIGH RESOLUTION SPECTROMETER

Spectrometers and spectroradiometers offer accurate information from distant objects, remotely observing radiation that the body reflects, e mits or absorbs. Spectroscopic techniques reach resolutions capable of identifying atomic and molecular species. The high-resolution spectrometer has 7 independent modules with linear array sensors that simultaneously measure a phenomenon. Each module observes a small range of the electromagnetic spectrum (~ 50nm) with a high resolution (resolution FWHM 0. 05nm and 0, 01nm/pixel), which when combined together generates a large spectrum equivalent. This enormous resolution allows solving atomic emission lines of different adjacent atoms for identification and quantification.

mits or absorbs. Spectroscopic techniques reach resolutions capable of identifying atomic and molecular species. The high-resolution spectrometer has 7 independent modules with linear array sensors that simultaneously measure a phenomenon. Each module observes a small range of the electromagnetic spectrum (~ 50nm) with a high resolution (resolution FWHM 0. 05nm and 0, 01nm/pixel), which when combined together generates a large spectrum equivalent. This enormous resolution allows solving atomic emission lines of different adjacent atoms for identification and quantification.

MICRO-LIDAR

Micro-LIDAR is a transportable optical device for active remote sensing of particulate matter emitted by pipes and boilers of biomass-fired stoves. It allows the monitoring of air quality in situ during environmental emergency events in areas saturated with particulate matter, for example, because of wood burning with a high moisture content ( >25% base humidity). An excitation laser beam generates retro scattered radiation when interacting elastically with the particulate matter contained in the smoke plume. A telescope detects light intensity returned to the device and it is quantified through an analog photocurrent measured by a photodiode, whose signal is digitized and range-corrected depending on the distance to the square from the smoke plume and compensated according to the intensity of the incidental laser.